Tolerances

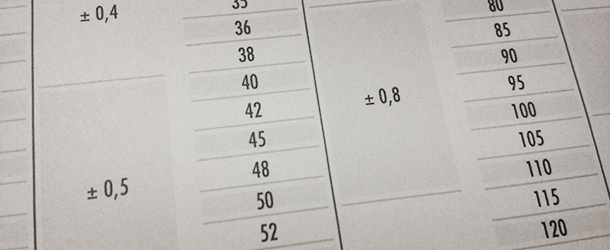

Diameter tolerances for hot rolled bars (UNI EN 10060:2004)

All of the measurements are expressed in mm.

| Diameter | Normal tolerance | Diameter | Normal tolerance | Diameter | Normal tolerance | Diameter | Normal tolerance |

| 10 | ± 0,4 | 30 | ± 0,6 | 70 | ± 1 | 140 | ± 2 |

| 12 | 32 | 73 | 145 | ||||

| 13 | 35 | 75 | 150 | ||||

| 14 | 36 | ± 0,8 | 80 | 155 | |||

| 15 | 38 | 85 | ± 1,3 | 160 | |||

| 16 | ± 0,5 | 40 | 90 | 165 | ± 2,5 | ||

| 18 | 42 | 95 | 170 | ||||

| 19 | 45 | 100 | 175 | ||||

| 20 | 48 | 105 | ± 1,5 | 180 | |||

| 22 | 50 | 110 | 190 | ||||

| 24 | 52 | ± 1 | 115 | 200 | |||

| 25 | 55 | 120 | 220 | ± 3 | |||

| 26 | ± 0,6 | 60 | 125 | ± 2 | 250 | ± 4 | |

| 27 | 63 | 130 | |||||

| 28 | 65 | 135 | |||||

The diameter of a bar, measured at any point at least 100 mm from the ends, must be within the tolerances indicated in the table. Unless otherwise agreed, shearing may deform the ends of the bars.

Straightness tolerances for hot rolled bars (UNI EN 10060:2004)

| Nominal diameter (mm) | Tolerance (mm) |

| d ≤ 25 25 < d ≤ 80 80 < d ≤ 250 | Not fixed q ≤ 0,4% di L q ≤ 0,25% di L |

Note: the straightness must be measured over the entire length of the bar.

Circularity tolerances for hot rolled bars (UNI EN 10060:2004)

The circularity or ovalization error is the difference between the largest and smallest diameter of the same section. It must be measured at least 100 mm from the ends of the bar and cannot exceed 75% of the diameter tolerance.

Tolerances for hot rolled coils (wire rods)

| Free-cutting steel wire rods, carburized, quenched and tempered, surface tempering, stainless | Steel wire rods for bolts and for cold forming | ||||

| Tolerances under standard prEN 10017:2002 | Tolerances under standard ISO CD 16124:2004 T1 | ||||

| Diameter (mm) | Tolerance (mm) | Diameter (mm) | Tolerance (mm) | ||

| from | to | from | to | ||

| 5,0 | 9,5 | ± 0,3 | 5,00 | 10,00 | ± 0,30 |

| 10,0 | 15,5 | ± 0,4 | 10,00 | 15,00 | ± 0,40 |

| 16,0 | 25,0 | ± 0,5 | 15,00 | 25,00 | ± 0,50 |

| 26,0 | 39,0 | ± 0,6 | 25,00 | 40,00 | ± 0,60 |

| 40,0 | 50,0 | ± 0,8 | 40,00 | 50,00 | ± 0,80 |

Circularity tolerances for hot-rolled coils (ISO CD 16124:2004)

The circularity or ovalization error is the difference between the largest and smallest diameter of the same section and cannot exceed 80% of the diameter tolerance.

Tolerances for cold-finished products in bars

Tolerance classes for cold finished products (UNI EN 10278:1999)

| Supply conditions | Tolerance class according to ISO 286-2 | |||||

| h7 | h8 | h9 | h10 | h11 | h12 | |

| Drawn | - | - | Round | Round | Round Hexagonal Square | Round Hexagonal Square |

| Peeled | - | - | Round | Round | Round | Round |

| Ground | Round | Round | Round | Round | Round | Round |

The dimensional tolerances must be chosen from among the admitted ones in the table.

Rodacciai standard dimensional tolerances for cold-finished products in bars

| Drawn round | Drawn hexagonal and square | Peeled | Ground | |

| Dimensional tolerances | h10 | h11 | h10 | h9 |

If not otherwise specified at the time of inquiry and order, the dimensional tolerances for the cold-finished bars will be those listed in the table.

Dimensional tolerances for cold-finished products in bars (UNI EN 10278:1999)

| Nominal dimensions (mm) | h7 | h8 | h9 | h10 | h11 | h12 | k13* | |

| from | to | |||||||

| 1 | 3 | 0,010 | 0,014 | 0,025 | 0,040 | 0,060 | 0,100 | +0,14 |

| 3 | 6 | 0,012 | 0,018 | 0,030 | 0,048 | 0,075 | 0,120 | +0,18 |

| 6 | 10 | 0,015 | 0,022 | 0,036 | 0,058 | 0,090 | 0,150 | +0,22 |

| 10 | 18 | 0,018 | 0,027 | 0,043 | 0,070 | 0,110 | 0,180 | +0,27 |

| 18 | 30 | 0,021 | 0,033 | 0,052 | 0,084 | 0,130 | 0,210 | +0,33 |

| 30 | 50 | 0,025 | 0,039 | 0,062 | 0,100 | 0,160 | 0,250 | +0,39 |

| 50 | 80 | 0,030 | 0,046 | 0,074 | 0,120 | 0,190 | 0,300 | +0,46 |

| 80 | 120 | 0,035 | 0,054 | 0,087 | 0,140 | 0,220 | 0,350 | +0,54 |

| 120 | 180 | 0,040 | 0,063 | 0,100 | 0,160 | 0,250 | 0,400 | +0,63 |

| 180 | 200 | 0,046 | 0,072 | 0,115 | 0,185 | 0,290 | 0,460 | +0,72 |

*= range not covered by the standard EN 10278. The k13 tolerance range is used by Rodacciai for the “iron metallurgy peeled” products made of stainless steel (1X execution). This deviation is greater than the nominal dimension.

In the tolerance “h”, the dimensions are all less than the nominal dimension. The maximum value coincides with the nominal dimension itself, while the extent of the tolerance range can be gleaned from the table.

The measurement of the actual diameter of the bar must be carried out at least 150 mm from the ends, as established by EN 10278.

Straightness tolerances for cold-finished products in bars (UNI EN 10278:1999

| Product shape | Steel group | Nominal diameter (mm) | Maximum deviation (mm) |

| Round | < 0,25% C | - | 1,0 |

| ≥ 0,25% C alloyed steels quenched and tempered steels | - | 1,5 | |

| stainless steels steels for tools | - | 1,0 | |

| Squares and hexagons | < 0,25% C | d ≤ 75 mm | 1,0 |

| ≥ 0,25% C alloyed steels quenched and tempered steels | d ≤ 75 mm | 2,0 | |

| stainless steels steels for tools | d ≤ 75 mm | 1,0 | |

| < 0,25% C | d > 75 mm | 1,5 | |

| ≥ 0,25% C alloyed steels quenched and tempered steels | d > 75 mm | 2,5 | |

| stainless steels steels for tools | d > 75 mm | 1,5 |

Unless otherwise specified, the tolerances in the table are applied.

Circularity tolerances for cold-finished products in bars (UNI EN 10278:1999)

The circularity error cannot be greater than half of the specified tolerance and in no case can be greater than the upper tolerance limit.

Tolerances for cold-finished products in coils

The reference standard is EN 10218-2:2012.

DOWNLOAD Tolerances

-

Tolerances

Tolerances for hot-rolled bars, tolerances for hot-rolled coils, cold-finished products tolerances in bars.